Deep Creek Marina Cleaning & Care

What causes mold & mildew to grow on your seats?

The two principal causes of offensive and unsightly stains and growths are bacteria and fungi, commonly called microorganisms. Bacteria are simple, single-celled organisms. Fungi, referred to as mold and mildew, are significantly more complex. A subset of fungal organisms is a type that produces colored by-products as part of its digestive process. These by-products are recognized as stains and are typically pink, yellow purple or black.

How do you keep mold & mildew from growing?

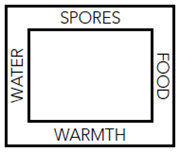

Break The Chain!

To have a mildew problem you need four elements, which are referred to as the Mildew Square. In order for mildew to proliferate, spores, food, warmth, & moisture are necessary. Elimination of one of these elements would break the square, and the mildew problem would be eliminated. The most likely element to control is moisture. Keep the surface dry and the ambient air dry and you can break the link in the Mildew Square. In actuality, this is very difficult. Marine upholstery may be dry when one sits on it, but it is constantly exposed to rain, spalshes, & wet bathing suits.

To decrease risk of Pink Stain:

Keep your boat free of dirt and debris, and upholstery as dry as possible

Clean frequently with mild soap and water, paying special attention to crevices

Always allow upholstery to dry completely!

Cover the boat when not in use, allowing for adequate venting

To learn more about Pink Stain...

Care and Cleaning Guide for Vinyl Coated Fabrics

Step 1

For light soiling, a solution of 10% household liquid dish soap in warm water, applied with a soft damp cloth. Run gently and rinse with a water dampened cloth.

Step 2

For heavy soiling, dampen a soft white cloth with a solution of 50% Formula 409® and 50% water or 50% Fantastik® and 50% water. Rub gently and rinse with a water dampened cloth.

Step 3

For more difficult stains, dampen a soft white cloth with a solution of household bleach (10% bleach and 90% water). Rub gently and rinse with a water dampened cloth to remove bleach concentration.

DO NOT USE WITH ALCOHOL BASED CLEANING AGENTS!

for a compete List of Spradling Approved Cleaners

*This information is not a guarantee and does not relieve the user from the responsibility of the proper and safe use of the product and all cleaning agents. The use of certain agents can be harmful to the surface appearance and lifespan of vinyl. Spradling, its agents and assigns assume no responsibility resulting from the use of such cleaning agents to the vinyl.

**Certain clothing and accessory dyes (such as those used on denim jeans) may migrate to lighter colors. This phenomenon is increased by humidity and temperature and is irreversible.

***Formula 409® is a registered trademark of the Clorox Company.® Fantastik® is a trademark of DowBrands, Inc. ® Trademark of the Dow Chemical Co. ® ©1997 Spradling International, Inc. ® Please check compatibility whenusing this product in combination with painted or varnished surfaces.

CANVAS CLEANING

Brush off any loose dirt. Hose down and clean with a natural soap. DO NOT USE DETERGENTS. STRONG SOLVENTS SUCH AS ACETONE, THINNER, AMMONIA, ETC., SHOULD NEVER BE USED. Rinse thoroughly to remove soap and air dry.

MAINTENANCE

Lubricate snaps and zippers regularly with a petroleum jelly and a cotton swab, or products such as vaseline or chapstick. Store in a dry, well ventilated area.

WARNING!

1) Tent poles must be used on cockpit and tonneau covers to prevent pooling, water that can damage the canvas.

2) Cockpit and Tonneau Covers are NOT intended for trailering purposes. Use of these covers while trailering can result in damage to the canvas and boat.

3) Never remove canvas by pulling roughly on one edge of the material. To prevent damage to the fabric, fasteners should be unsnapped as close to each button as possible.

Importance of Impeller Care

EVERY 2 YEARS!

The cooling system of a boat motor is one of the most vital necessities it can have. Worn or damaged water pump/impeller, clogged passages, cracked/kinked hoses, among other things can easily create an overheat condition, which is one of the deadliest conditions a motor can face. Overheating can and does cause premature failure due to swelling of pistons and rings in the cylinder bore, warping and/or cracking of cylinder heads, blown cylinder head gaskets, degradation of oil lubricating properties, etc. The cooling system of a marine engine is armed with an electronic audio alert device simpy called a "warning horn." If you hear a shrill high pitch sound coming from under the dash, or from the throttle box while under power, heed the warning, and do not continue operation of motor. You should also test the function of the warning horn periodically by disconnecting the brown wire to a good known ground source. Warning horn should sound off, if not, horn and/or wire needs to be checked or replaced.

There are two types of cooling systems commonly found on inboard/outboard boat motors.

Figure 1

shows a typical fresh water dependent cooling system. With this system, the motor is totally dependent of fresh water being present to provide proper cooling characteristics. Fresh water is normally drawn by a belt driven pump from a thru hull fitting in hull of boat on inboards, or by water pump in stern drive through the lower unit water passages on an inboard/outboard, and then exits the boat through the exhaust.

Figure 2

Shows the typical "enclosed" cooling system. This configuration utilizes contained antifreeze in the main part of the motor and also uses a heat exchanger much like the purpose of a radiator in an automotive application. The difference being instead of relying on air flow to cool the antifreeze, fresh seawater is pumped through the heat exchanger and then exits the boat through the exhaust.

Now that you hopefully understand the basics of the cooling system, let's look at the source of the process, and the things that can go wrong, causing an overheat situation.

Figure 3

Shows a typical belt driven seawater driven pump. This pump is the heart of the cooling system, and if anything goes wrong here, an overheat problem is inevitable. Failures can include worn or damaged impeller, worn or damaged housing, and impeller shaft lock up. It is recommended that the impeller be changed every two years regardless of amount of usage. An impeller will usually go bad due to dry rot from non-usage, rather than being worn out from excessive usage, and can also be damaged from running motor with insufficient water supply. When replacing the impeller, make sure to apply a thin layer of lightweight grease to the inner surface of the impeller housing. Damage to the pump housing can be caused from lack of winterization procedures, and/or running motor with insufficient water supply. If the shaft locks up, there is no real way to service, so the pump must be replaced as a whole.

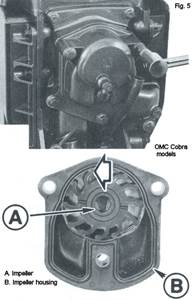

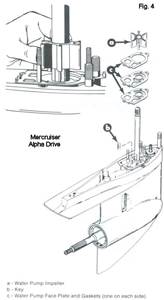

Figures 4 & 5

Show the location of the water pump located in stern drive. Failures here are typically the same as in Figure 3, except that shaft lock up does not usually occur. If it does, you've got much bigger problems, and you need to refer to the drive section for further information.

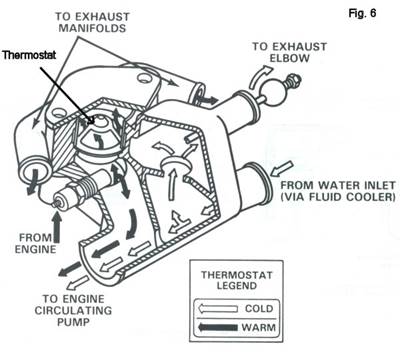

The next possible culprit of an overheating problem in the cooling system is the thermostat.

Figure 6

Shows the typical thermostat arrangement in the thermostat housing. Most thermostats are designed to open at 160 degrees water temperature. As long as the thermostat opens as designed, everything is fine. If it doesn't, then overheating will surely result. To test the thermostat, remove and place in pan of water on cook stove. With a reliable thermometer, heat water until thermostat opens. It should open at approximately 160 degrees. If it does not, discard and replace with new thermostat

Finally, the third most common reason of an overheat problem with the cooling system can be attributed to clogged water passages, usually in the exhaust manifolds. Since most exhaust manifolds are made of cast iron, rust and corrosion are always present. If you have an overheating problem, and the impeller and thermostat are in good shape, remove the riser from the exhaust manifold (Figure 7) and inspect water passages for blockage. If the passages are blocked, it's basically the same thing as the thermostat not opening, and water circulation is not allowed to escape through exhaust as designed.

In summary, change water pump without fail EVERY two years regardless of usage. Also, if you operate your boat in salt water, make sure to flush your engine and cooling system after every use. Following these simple guidelines will protect your marine engine from serious damage, and the mechanical skills required are fairly minimal. If you have any questions, feel free to contact us.